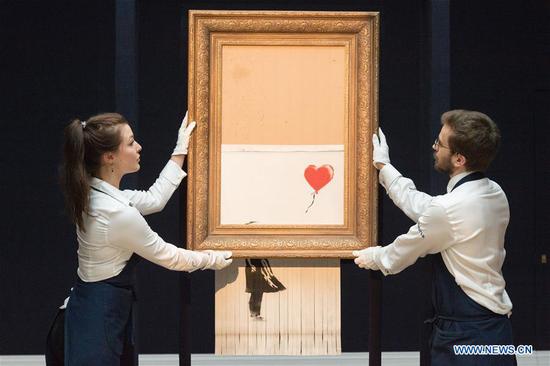

Employees work on the production line at the Lida (Ethiopia) Textiles Jean Factory in the Eastern Industrial Zone. (Photo by Xiao Xiangyi/China Daily)

Three objectives

Belay Heilemichael, area manager of the Ethiopia Investment Commission, told TV news channel CGTN about the services provided by the Hawassa Industrial Park, which was built by China Civil Engineering Construction Corp.

"There are three objectives," he said. "The first is to generate foreign currency; the second is to implement opportunity; the third is technology transfer. ... The investors should not have to go outside of the park to get services. All services, banking services, even visa services, will be provided there. To ensure success here, the government has a one-stop service center where investors can even get their visas and residence permits."

He added that the companies in the industrial park will be able to generate export revenue of up to $1 billion and hire up to 100,000 people.

Tao Huixing, director of the Eastern Industrial Zone managing committee, said companies locate there because the park provides complete utilities and a one-stop service for all their needs.

The parent company of the Eastern Industrial Zone, Jiangsu Qiyuan Group, has invested about $200 million in the park for infrastructure such as power, water and other connections. Jiangsu Qiyuan, based in Zhangjiagang, near Suzhou, Jiangsu province, is a small, private producer of precision metal products.

In addition, the companies at the park - mostly Chinese, although there are local ones as well as those from India, the US and the Netherlands - have invested a further $400 million, Tao said.

Regarding Qiyuan's decision in 2008 to begin building the Eastern Industrial Zone, Tao said: "A lot of China's low-wage industry will move here. In China, wages used to be very low, but now they are quite high. For some labor-intensive industries, it is very difficult to survive because of the increased labor cost. Here, wages are much, much lower - less than 10 percent of Chinese wages."

Ethiopia has about 45 million people of prime working age between 18 and 50, he said.

"About 10 years ago, China's economy was already very big. We encountered many trade restrictions limiting exports to Europe and America, especially textiles, garments, televisions and some tech products. In these circumstances, the Chinese government said "if you all stay in China, then it will be more difficult. Labor costs have increased, so you should find a new place overseas'," Tao said.

"Chinese companies are experienced in these things, because at an early stage of our opening-up we also did things like this.

"In the early '80s, the Chinese government created business-friendly policies and encouraged Chinese companies to expand exports. This policy had a very good effect. After five or six years, Chinese companies had a lot of foreign currency and could use it to import advanced production machinery from Europe, America and Japan," he said.

China Daily recently visited five Chinese manufacturers in Ethiopia that illustrate the opportunities and challenges companies are finding in the country and throughout Africa.

Companies making shoes and jeans are prototypical low-wage manufacturers, although the shoe factory exports its products, while the jeans plant targets the local market.

Factories that make glass, ceramic tiles and aluminum window casings produce substitutes for imported products needed for Ethiopia's building boom, but their strategies are not so dependent on large numbers of low-wage workers.

Garment manufacturing, which depends on a large, relatively low-skilled workforce, is a good example of the kind of industry that has found a comparative advantage in Africa.

For example, Lida (Ethiopia) Textile, in the Eastern Industrial Zone, makes jeans that are sold in Ethiopian markets. The factory began production in September last year and was profitable by November, said Liu Jianxun, its director. He said that although the jeans reduce Ethiopian imports, many of the raw materials, especially cotton, must still be imported from China.

Similarly, Dongguan Huajian Group, a large Chinese shoemaker, built a factory and industrial park in Addis Ababa. The company employs 6,000 Ethiopian workers and plans to expand this to 15,000 soon, and possibly to 100,000 eventually.

Glass manufacturing reduces Ethiopia's dependence on imports for use in its building boom. But making glass requires highly experienced management, a large investment in equipment and a workforce that is better-skilled, according to Liu Jun, sales and marketing manager of Ethiopia Hansom International Glass Co, a subsidiary of CGC Overseas Construction Group in Addis Ababa.

"If the electricity goes down for even seven minutes, the machinery can be destroyed because the flow of cooling water is stopped. So we have five backup generators. There are many cement factories in Ethiopia. If a problem happens, they just stop. But glass factories are different. Here, we run 24 hours a day, every day. In five years, we have not stopped for even one minute," Liu said.

"Before they came here, our Chinese employees worked in glass factories. They had 10 to 20 years' experience. Local workers only have one or two years' experience, maybe five years," Liu said, adding that there are about 80 Chinese employees at the company and 250 Ethiopians.

Hansom is the only glass manufacturer in Ethiopia, but its profits are not very high because the government has told the company that it needs to control its prices, Liu said.

Huajia Aluminum produces window frames for the local market. Cai Jinfeng, the company's factory manager, said: "When we first came to Addis Ababa several years ago, many buildings in the city had empty holes in the wall for windows. So, we decided to open an aluminum factory instead of making plastic tubes like our mother company in China. The factory started to produce a year ago and is just starting to make a profit. Most of the raw materials are imported from China. We have only 10 to 15 percent Chinese employees; the rest are Ethiopian workers."