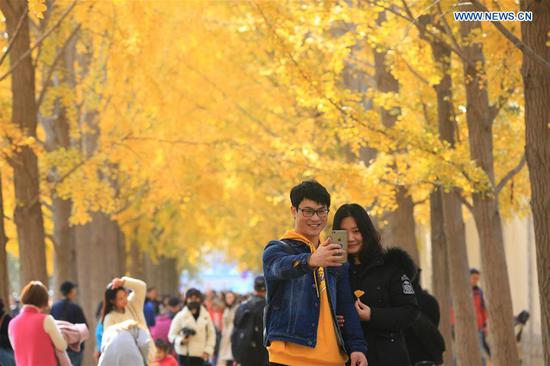

Employees check vehicles produced by BMW Brilliance Automotive Co Ltd in Shenyang, Liaoning Province. (Photo provided to China Daily)

I was born into a worker's family. My father taught me it is important to have some skills to make a living.

At 18, I went to a local vocational school. After two years, in 2001, I became a skilled worker at the Brilliance factory.

First working as a technician at the plant, I had many difficulties identifying where the problems were. Then, I started to learn metal plate skills on the production line from experienced workers.

As my mentor instructed, I would go to the place where the sparks flew. During my spare time, I usually delved into production techniques.

Without taking a day off, I honed my skills over three years and got an offer to become the production line monitor.

Even then, I continued to improve my skills.

In assembling a car, an important skill is running your hand over its surface. To master that skill, I touched more than 300 vehicles to find every flaw on their surfaces.

I also got some opportunities because of the skills I learned. In 2005, a German technician offered me an opportunity at the BMW AG plant in Germany, but I turned it down. In my mind, the China motor bus is what I should be most proud of, since it represents a national brand.

At the beginning of 2006, I got another opportunity to coach workers in Egypt for Brilliance overseas. The native Egyptian workers also acknowledged my skills as I found a small bug under the car's hood that confused them for several months.

As a technician at the Brilliance factory, I got more than I expected.

In the future, I hope my skills will help more workers in the automobile manufacturing industry and make the national brand better known overseas.