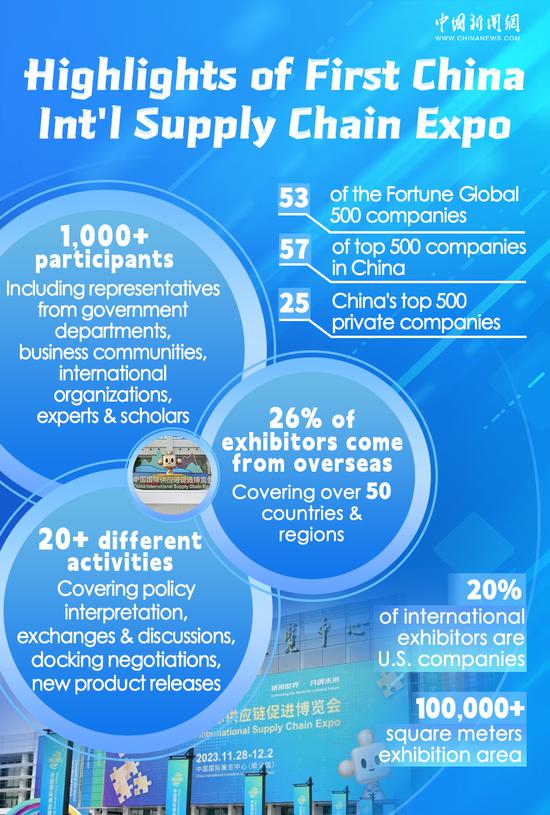

A view of Apple Inc's booth at the ongoing first China International Supply Chain Expo in Beijing. (WANG JING/CHINA DAILY)

Apple Inc is deepening cooperation with Chinese suppliers in the area of smart manufacturing, a senior executive said, as domestic companies sharpen their technological edge and develop advanced automation equipment and solutions.

"Chinese suppliers have grown very fast and become an indispensable and particularly important part of our supply chain over the past 30 years," Isabel Ge Mahe, vice-president and managing director of Apple Greater China, told China Daily on the sidelines of the ongoing China International Supply Chain Expo in Beijing.

Currently, 151 of Apple's 200 major suppliers, including foreign and Chinese ones, have a manufacturing presence in China.

"Chinese suppliers are world-leading in their technologies," she said, adding that Apple is happy and willing to help the country transition to intelligent manufacturing.

The trend of localization of intelligent manufacturing equipment has been "obvious" in the past decades of cooperation between Apple and Chinese suppliers, she added.

There is close collaboration between Apple's engineers and supply chain engineers in smart manufacturing. Apple engineers bring new technologies such as artificial intelligence and machine learning to the production lines, and also some of the latest materials and manufacturing processes to the supply chain, helping it move toward intelligent manufacturing, Apple said.

Previously, intelligent manufacturing equipment in Apple's supply chains came mainly from non-Chinese companies, but now such equipment of local origin has become more common, she said.

Iris Cui, vice-president of Asia procurement and operations at Apple, said this transformation of intelligent manufacturing is mainly reflected in three aspects: talent, technology and equipment.

In terms of equipment, about 75 percent of Apple supply chains' spending on smart manufacturing equipment is used to buy Chinese-developed ones.

Dong Hao, vice-president of marketing at Bozhon Precision Industry Technology Co Ltd, said that the company has, since 2010, become Apple's automation equipment supplier, covering a wider range of products, from initially standalone devices to fully automated intelligent flexible production equipment.

Dong said the company delivers several thousand types of equipment to Apple each year, for more than 180 factories in 13 countries. Through cooperation with Apple's supply chain, Bozhon Precision has also promoted its internationalization process.

Zhou Qunfei, founder of Chinese glass and touch-screen maker Lens Technology, said: "Smart manufacturing and automation can help us boost efficiency and improve the qualified rate of products. It is a must-choose road for us."

According to Zhou, the company aims to invest more to boost the automation level of its assembly lines from about 70 percent to 90 percent in the future.

Bai Ming, a researcher at the Chinese Academy of International Trade and Economic Cooperation, said China has advantages in terms of its market, technology and talent, and its innovation-driven development strategy will help the nation become more important to the growth of global tech giants, such as Apple.

京公网安备 11010202009201号

京公网安备 11010202009201号