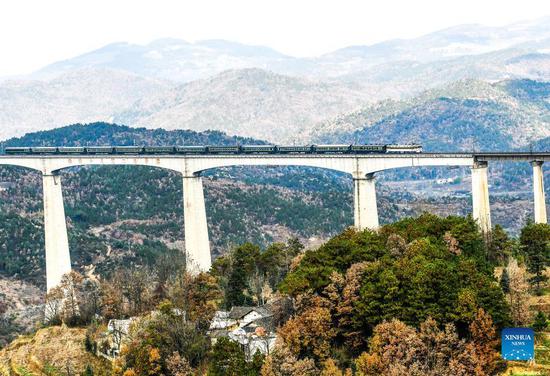

Work is carried out at the construction site for Michurinsky Prospekt station. (REN QI/CHINA DAILY)

Rich experience

During a media interview, former deputy mayor of Moscow Marat Khusnullin hailed CRCC's rich experience in subway construction.

Work on building the new line in Moscow was extremely difficult, and there were also issues such as the climate, topography and language differences to contend with. In addition, the COVID-19 pandemic posed a number of threats.

"To meet strong demand for transportation design in Moscow, the complicated application process, as well as requirements for a high standard, our company established a design department," Kong said.

He added that the department sees local standards as the basis for design, regards local engineers as its "design core", and insists on using local experts and consultancy companies as technical support.

Chinese engineers assume responsibility for design quality and progress, Kong added.

In addition to communication between CRCC and its Russian partners, extremely low temperatures posed another challenge to subway construction work in Moscow.

Five Chinese-made shield machines more than 6 meters in diameter, and one with an 11-meter diameter, assisted in the joint construction work to ensure safety.

Six machines operated in temperatures below-30 C. Those more than 6 meters in diameter were named Polina, Maria, Daria, Evgenia and Galina, after the daughters in the Russian television production Father's Daughters.

Liu Xing, deputy manager of engineering at CRCC Rus, said that with their high quality and efficiency, Chinese shield machines have won acclaim from the Russian government, and helped boost Chinese manufacturing exports to Europe.

The machines feature a Chinese-designed nonstop belt delivery system, and can operate continuously in extremely low temperatures, accelerating the construction process twofold, Liu added.

京公网安备 11010202009201号

京公网安备 11010202009201号