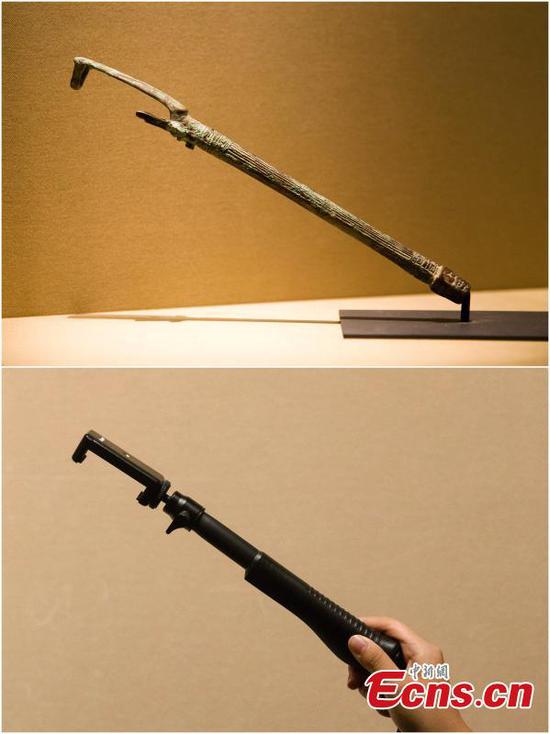

(ECNS) -- A third generation train body cleaner independently developed by Xinjiang's railway staff has been put into operation at the Kashgar vehicle servicing depot in the Xinjiang Uygur Autonomous Region.

The cleaner can automatically clean trains with powerful rotating brushes. In the past it took nearly two hours to clean a train, but now an 18-carriage train can be done within 10 minutes.

Train body cleaning is the first procedure in vehicle servicing. Rail lines in south Xinjiang usually suffer through heavy dust, making train surface cleaning time-consuming and laborious. The new cleaner improves vehicle servicing efficiency and lowers the procurement cost of cleaning equipment.

Based on the previous two generations of cleaners, developers have installed crawlers below the roller brushes, allowing them to move and carry out cleaning work through power control.

The research team consists of nine mechanical fitters. According to Zhang Dianhua, a senior technician, they began developing the cleaner in March 2020 in a bid to cut investment.

Zhang’s team independently completed the welding and assembling, while the research team installed a water circulation system inside the water tank of the cleaner. The design achievements of the third generation cleaner are applying for patents now.