An exhibition of an unattended vending car built by PIX, a start-up based in Guiyang, Southwest China's Guizhou Province (Photo/Courtesy of PIX)

Imagine waking up and making a reservation for a robot-staffed vending car first thing in the morning so you can enjoy a cup of coffee on the way to work. After work, you get some exercise on the way home via a moving gym.

Then a mobile grocery store stops right in front of your door when you arrive home. You select fresh vegetables and ingredients to cook a delicious dinner.

PIX claims it will be the first in China to make this convenient future possible.

The start-up was incubated in Silicon Valley and is based in the Guiyang Hi-tech Industrial Development Area in Southwest China's Guizhou Province.

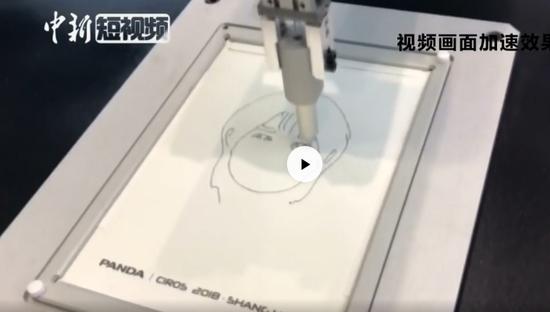

The company's offices impress visitors, as they are greeted by a well-designed black and white vehicle - a "multifunctional future mobility space" powered by self-driving technology.

It is an unattended vending car with a robot that can make coffee. When a customer scans a QR code, the robot barista will whip up a cup of the caffeinated beverage.

Cao Yuteng, chief operating officer of PIX, told the Global Times on June 28 that the vending car will soon enter service in Guiyang's Wanda Plaza in July.

PIX will obtain a self-driving car test license from Guizhou authorities this year, said Cao.

"Besides the vending car, PIX builds multifunctional mobility spaces for various application scenarios, such as self-driving theaters, driverless shuttle vehicles and autonomous logistics cargo," Cao said, noting a group of PIX vehicles will be put into use in Guiyang in the second half of this year.

"What we make is not cars, but moving real estate and brand-new living spaces. In the past 100 years, what users have cared about has been the brand, performance and price of cars. But in the future, they will care about what services cars provide, such as cafe, hotel, karaoke or office space amenities," Cao said.

The speed of the cars is limited to around 20 kilometers per hour to maintain passengers' safety.

Meanwhile, the company has established the world's first database of traffic police gestures to train the vehicles.

PIX has developed a by-wire kit - including a vehicle control unit (VCU), electric steering unit (ESU), electric brake unit (EBU) and computing - to control the vehicle.

According to the controller area network (CAN) message received, these units can control the vehicle lights, accelerator, steering wheel, brakes and other components.

With a modular design, these cars can be used in industrial parks, theme parks, large communities and airports, or could even be used to build a new town based on multifunctional self-moving vehicles, according to Cao.

Some large brands such as domestic dairy powerhouse Mengniu, real estate developer China Vanke and US coffee giant Starbucks have expressed interest in purchasing this car with customized services, he said.

The company has also set up an open source community online called the Moving Developer Community, aiming to solve common problems in self-driving technology through collaboration and eventually make the solutions available through an open source license.

The community has attracted hundreds of top engineers from all over the world.

In March, PIX brought together over 30 engineers from 11 countries and transformed a traditional car into a self-driving one in five days.

Decentralized manufacturing

Besides R&D, PIX also has an intelligent manufacturing factory of 5,000 square meters, which has metal 3D printing, composite material formation and a variety of test machines. The start-up is using the equipment to manufacture cars in small batches on its own.

It has also partnered with a domestic car factory from Guiyang for mass production.

Traditional manufacturing and high productivity do not mean a faster response to user demands. The real revolution within the car industry will begin with the way cars are manufactured, Cao said.

"We are creating a decentralized and distributed way of manufacturing," Cao said, noting the factory is reducing unnecessary car parts by 90 percent.

Distributed manufacturing enables a faster response to customer needs, reducing manufacturing costs by 60 percent.