A new method for extracting lithium in a greener and more efficient way has passed China's state-level appraisal, paving way for its commercialization to boost the new energy sector.

Qiu Zumin, professor of the institute of environmental science and engineering in Nanchang University, said the new lithium extraction technology has passed the national scientific and technological achievements appraisal. It is expected to replace current lithium extraction methods in China, which have been blamed for producing huge amounts of waste, and have low profitability.

Lithium batteries are essential to power modern electronic devices, such as mobile phones, laptops and electronic cars. Lithium is also used in medicine, pottery, glass and other industries.

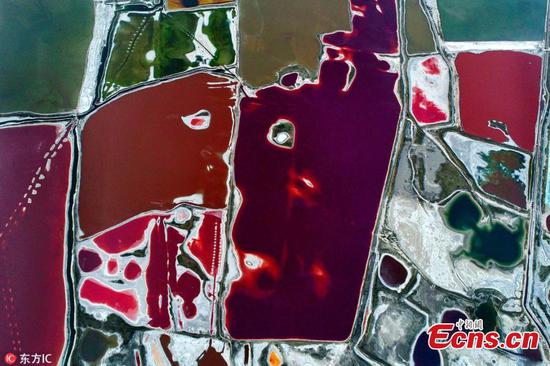

Lithium cells rely on lithium carbonate as the raw material. China imports 80 percent of its lithium carbonate, though it is rich in lithium resources, due to backward mining technology.

With traditional methods, 30-40 tons of waste are produced in making 1 tonne of lithium carbonate. It is also very costly to treat the waste.

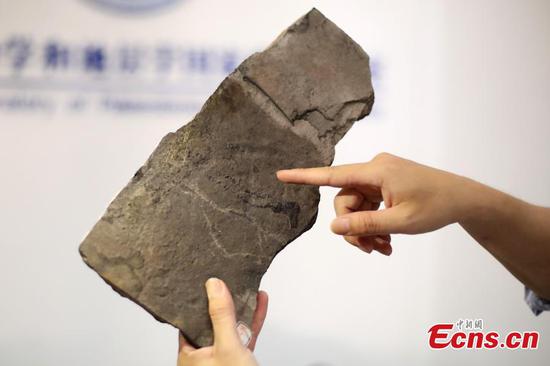

The new method is jointly developed by the Jiangxi Haohai Lithium Energy, Nanchang University and other institutions. It can separate all the elements in lithium micas.

Peng Guiyong, chair of Haohai, said the company plans to invest 1 billion yuan (156 million U.S. dollars) to build a production line with an annual capacity of 40,000 tonnes of lithium carbonate.

Jiangxi boasts the world's largest lithium mica mine. The province's reserve of lithium oxide accounts for one-third of China's total.