The vast expanses of Gobi deserts in northwest China's Xinjiang Uygur Autonomous Region are normally devoid of life, yet this is where numerous tall futuristic iron structures glow in the dark throughout the night.

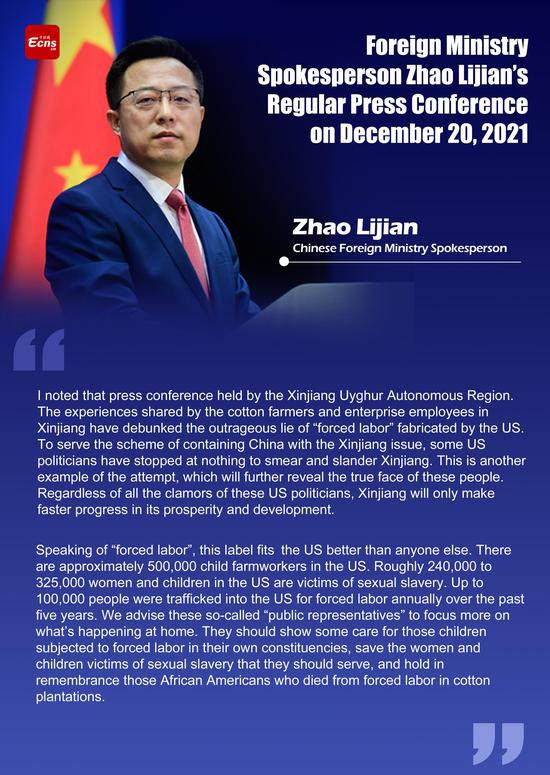

These buildings belong to one of China's largest producers of polysilicon, an essential material component in the solar photovoltaic manufacturing industry. The leading industrial player was thrust into the global spotlight in June when it, along with three other Xinjiang-based companies, was sanctioned by the United States over accusations of so-called "forced labor."

Although the surrounding wilderness of the Gobi desert doesn't appear to be a cradle of the high-tech industry, the company chose Xinjiang for good reason.

Xinjiang is rich in quartz ore, the raw materials for extracting industrial silicon, and it offers companies lower electricity costs thanks to its abundant energy resources, the company's technical director told Xinhua in an exclusive interview, on condition of anonymity, adding that many polysilicon producers are drawn to the region over these advantages.

Xinjiang is the largest production region of polysilicon in China, accounting for over half of the country's total polysilicon production capacity.

The technical director, who has been working in the silicon sector for over a decade, said the U.S. "forced-labor" accusation could not hold water at all as the factory, like many silicon producers, enjoys a high level of automation.

"The majority of the production stages are highly automated. Technicians can manage production work from operation control rooms, with on-spot checks requiring a few production line workers," the technical director said.

It is common knowledge that polysilicon production is not a labor-intensive sector, but a capital-and-technology-intensive one, noted Pan Cunxiang, secretary-general of the non-ferrous metal industry association in Xinjiang.

"For example, the labor demand has been cut by about 50 percent now from over a decade ago thanks to the introduction of automation devices," Pan said.

The factory is home to over 800 workers, including those of ethnic minority groups. Besides, the workers chose to work in this factory for good reason. In addition to free accommodation and recreation facilities, the monthly pay averages 7,000 yuan (about 1,100 U.S. dollars) to 9,000 yuan for ordinary workers, a lucrative income compared with many other industries.

Alimu, a 26-year-old Uygur employee, was one of the first batches of workers to join the company. "Upon graduation, the company came to my college for recruitment. As a chemical engineering major, I knew little about silicon, but I was attracted by the promising future of the new energy sector."

After working in the company for five years, Alimu can earn over 10,000 yuan each month as a production safety supervisor.

Despite the U.S. sanction, the company saw the strongest market performance in a decade, according to its technical director.

In view of the goals of peaking its carbon dioxide emissions before 2030 and achieving carbon neutrality before 2060, China is speeding up the transformation to a clean and low-carbon energy consumption structure. The strong end-market environment resulted in stronger-than-expected downstream demand that continues to push up polysilicon market prices.

Alimu's wife, a kindergarten teacher in his hometown about 200 km away from the company, is expecting a child next April. Although the work locations are at different places, the two have decided that Alimu will continue to work at the polysilicon company for the foreseeable future.

"I bought a car in the first year of work. It takes less than three hours to drive to my hometown," Alimu said. "I will strive for a higher position such as the chief safety officer to create a better life for my family."

京公网安备 11010202009201号

京公网安备 11010202009201号